EXPERT TIPS: THE CARE AND FEEDING OF YOUR CASTLE MOTOR

We understand that your R/C equipment is more than just a hobby—it's an investment of your time, energy, and passion. That's why this guide is designed to safeguard your investment and help you extract every ounce of performance from your Castle Creations motor. From initial setup to advanced troubleshooting, we've got you covered.

Motor Selection

In the R/C Car world the overall power a system will draw, and the heat generated, is determined by vehicle weight, gearing, battery voltage, terrain, driving style, and motor efficiency. The reason that Castle Creations chooses not to publish maximum amps or wattage is because it would not be particularly helpful in determining if the motor would be applicable for a vehicle. Instead, we rate the controller/motor for a particular application, usually based on the type of vehicle, vehicle weight and number of LiPo cells. Castle provides recommendations for all surface products that relate to the size, number of driving wheels, and weight of the vehicle it’s installed in. This information can be found on the product pages of the Castle website. (see example below)

Sensored or Sensorless?

Check out this blog article right here for an in depth dive into SENSORED VS SENSORLESS.

Castle is now producing only sensored motors and will no longer be producing sensorless motors. The motors will install into your application the same way as your replaced sensorless motor; they will also have the same performance as your sensorless motor. Below are answers to the most burning questions regarding this transition.

Can I run a sensored motor on a non-sensored ESC (IE Sidewinder 3 or Mamba Monster 2)?

Absolutely! But you will not be able to utilize the sensored capabilities of the motor. The ESC will simply run the motor sensorless; it will perform exactly the same as a non-sensored motor. Just connect the three primary motor wires and set aside the sensor cable that came with the motor. There is no disadvantage to running a sensored motor on a non-sensored ESC and you still have the serviceable advantages referenced on the previous question.

Why are you selling sensored motors with sensorless ESCs?

Because our sensored motors can run sensorless, has identical performance characteristics and costs the same as a sensorless motor it was not logical to continue to produce a sensorless only version; the sensored version can work just as well running sensorless so we streamlined our part numbers, inventory and manufacturing and will only be producing sensored motors in the future. Again there is no disadvantage to running a sensored motor on a non-sensored ESC.

Are sensored motors waterproof or water resistant?

They are water resistant. We have added a double silicone conformal coating to the sensor circuit board to give it a level of water resistance. There are some precautions that need to be taken for reliable sensored operation and prolonged life. It is recommended to apply dielectric grease to the outside of the sensor port of the motor while the sensor wire is installed; if water gets in the sensor connection the motor will still operate, but it will operate in sensorless mode. Please refer the document “Running and Maintaining Castle Motors in Wet Conditions”

Shaft Size

5mm vs 3.2mm shaft size

Obviously, you must match your pinion gear to motor shaft size. If your vehicle has massive power and torque and is run in abusive environments, a larger shaft may be the best choice.

Shaft sizes include 2mm, 1/8” (3.2mm), 5mm, and 8mm,; with 2mm used in 1/18th, 1/8” (3.2mm) being the most common for 1/14th and lighter 1/10th vehicles, 5mm for heavier 1/10th and 1/8th, and 8mm for 1/6th scale and larger.

It really comes down to a strength issue, or shaft size, but adapter sleeves are available to convert 5mm pinions to 1/8” if necessary. Castle offers several motors that come in both 3.2mm and 5mm shaft sizes. Castle also offers a wide range of pinion gears.

Wire

High strand count silicone coated copper wire is essential with higher power electric power systems. Castle Creations' wire (on motors and ESC) is lower resistance than the same diameter of solid copper, meaning more power gets from the batteries to the motor with less wasted as heat. The ultra-high strand count and silicone coating means the wire is very flexible which prevents hardening and breakage with use. Our wire is available for purchase and this link provides the appropriate wire gauge for your Castle ESC. (Link: http://www.castlecreations.com/wire-application-chart)

Wire Length

Motor wires can absolutely be shortened, with the exception of our 1/18th scale 0808 motors. In fact, the shorter the wires the better (in high-speed setups this equals less resistance), they are only too short if they can’t connect to the ESC. :)

Note: It takes a very hot soldering iron to get a good connection. It can be very difficult to solder to the solder tabs; it is best to do it on the bullet connector end. Cut to length, unsolder bullets from removed wire, solder bullets onto shortened wires, then add new heat shrink. Let us know if you would like to see more on this subject!

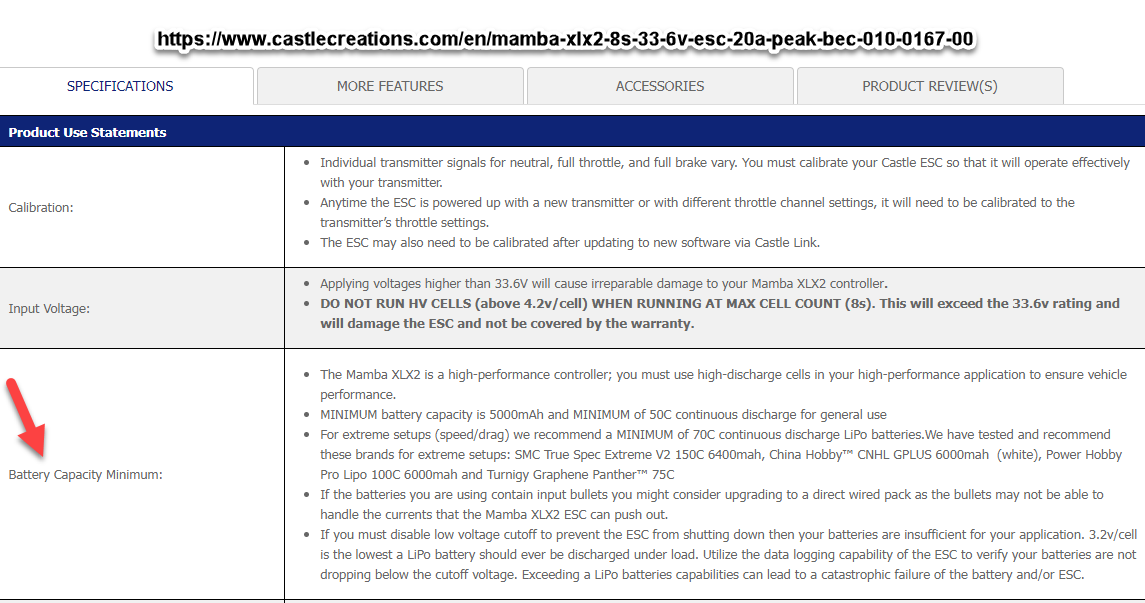

Batteries

As with any extremely high-powered electric power system, the primary limitations to ultimate vehicle performance are the batteries and connectors. When choosing a LiPo battery for your brushless motor and/or ESC, you should refer to Castle’s published battery capacity minimums to ensure your chosen batteries are suitable for the maximum current demands of a particular ESC/motor combination. This information can be found on the product pages of the Castle website.

Website specifications example.

Gearing

Always start with the smallest pinion and largest spur available for your application.

Pinion and spur gear sizes refer to tooth count. The pinion is the small gear on the motor and the spur is the large one attached to the car.

Gear down = more gear reduction, less motor load, theoretically less top speed. Smaller pinion (and/or larger spur).

Gear up = less gear reduction, more motor load, theoretically more top speed (Larger pinion (and/or smaller spur).

The goal here is to not overheat the motor. Always check your motor temperature frequently on the first run after changing the gearing, motor or increasing battery voltage. Use an infrared temperature gun (like this one) to monitor motor temps and If the motor starts to get close to 180° reduce the pinion size, increase the spur size, or reduce the battery pack voltage.

Castle also offers a wide range of pinion gears.

Over Voltage

If your ESC is capable of running up to 6s LiPo you must ensure that the motor is capable of the same. Always use the lesser of the two values otherwise. There is a phenomenon that occurs when increasing the number of cells from say, 4s to 6s, on a motor that is rated at 4s. It is essentially increasing the voltage by 50 % (6/4 = 1.5). Voltage affects motor speed, so the motor will want to turn 50 % faster on 6s than on 4s. To do this, the motor will draw more current to overcome internal losses and the inertia of the car. As the load of the motor increases, the current increases. Current in brushless motor windings produces waste heat. Too much heat in your motor will lead to failure of the motor windings. End of story.

Free-Revving

The act of free-revving, running a brushless motor at high RPM under no or little load for an extended period of time, can cause damage and subsequent failure of a brushless motor and/or an ESC. If allowed to accelerate too high, the rotor can break apart, causing an immediate halt in the rotation of a brushless motor. Not only will this damage the internals of a brushless motor, but in some instances, can damage the ESC as well. The likelihood of a rotor failure is significantly increased if a brushless motor is free-revved while hot, such as after a full-battery pack run. Because brushless motors can attain such high RPM under no – or low – load conditions, the centrifugal forces in the rotor can cause it to break apart. We recommend that you never free-rev your brushless motor in or out of your vehicle. Any damage sustained from free revving is not covered under Castle Creations warranty and besides, it’s dangerous to you and those around you.

Wiring-Motor Connection

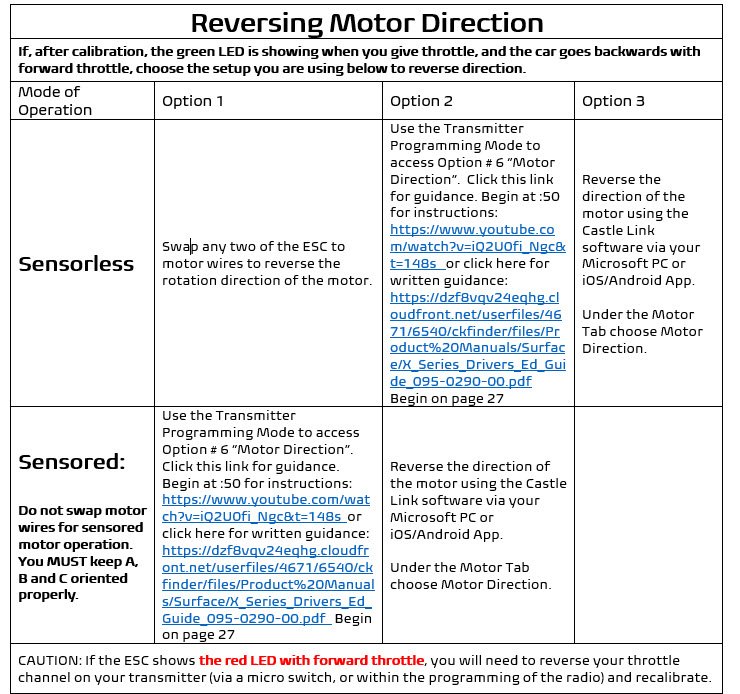

For sensored operation, the motor’s wires must connect to their corresponding letters on the ESC (A-B-C) in order to utilize the Hall sensors within the motor. If you aren't going to utilize the hall sensors (the sensor harness is not connected and you intend to run it sensorless), then you can hook up the three drive wires any way without causing internal damage and/or catastrophic failure to the ESC.

Sensored Motor Quick Setup

Contamination

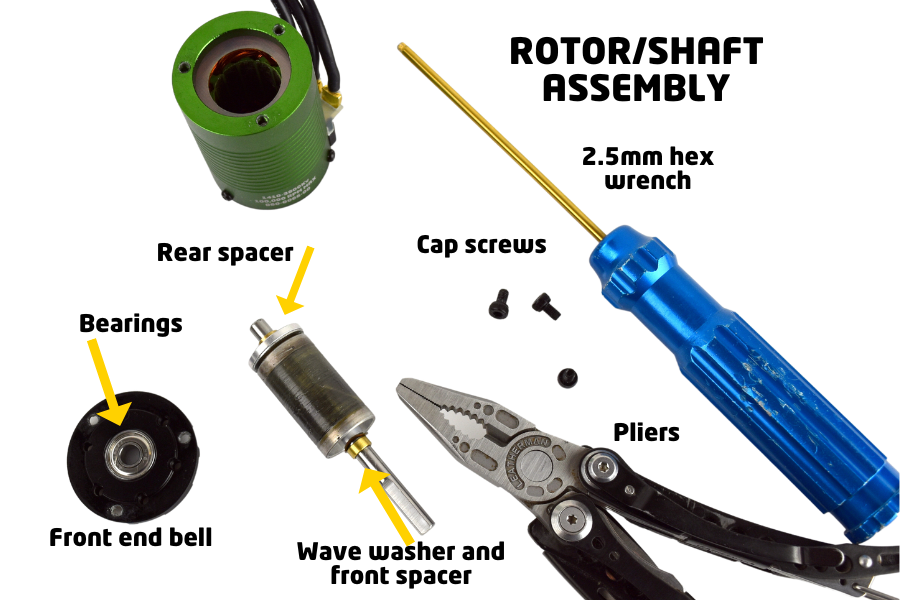

Contamination from dust, dirt and gravel is one of the leading causes of motor failure. Foreign bodies which find their way inside the motor can dent bearing raceways and balls, leading to high levels of vibration and wear. It can also block the motor cooling fan (if installed), limiting the motor’s ability to regulate its temperature, and increasing the likelihood of overheating. Brushless motors have very few parts, so it’s easy to take them apart for cleaning. Remove the screws, disassemble the motor and lay the parts on a clean surface. Be sure you don’t lose any spacers or washers that are used to properly align the motor shaft (and magnets) inside the motor. Please refer the document “Running and Maintaining Castle Motors in Wet Conditions” for more details. Also note the order in which the spacers or washers are installed! Castle offers motor endbell and rotor/shaft replacement kits for the 14 Series and 15 Series motor offerings. https://www.castlecreations.com/en/motor-service-parts

Maintaining Motors in Wet Conditions

Rotor/Shaft Assembly

Although Castle sensored and sensorless motors are not affected by water while they are running, the water can wreak havoc to the steel components when you store them; rusting of the bearings and the stator can cause major issues down the road. So, our motors need some TLC and maintenance to keep your vehicle “over-powered”. You can ride them hard, but it’s not recommended to put them away wet. For excessively dirty water, rinse with clean water under a faucet before drying.

The sensor wire connections (sensored operation) can be affected by water and may cause momentary loss of sensored capabilities. Applying a small amount of dielectric grease (non-curing silicone compound ideal for sealing, protecting and insulating electrical components and connectors) to the outside of the sensor wire connections can help keep water from causing loss of contact with the sensors; do NOT apply the grease directly to the ports as this will prevent proper connection.

Adding dielectric grease to the sensor port on the ESC side is just as important as doing it on the motor side. If using a sensor harness and standard sensor wire, you'll want to apply dielectric grease at that connection as well. We recommend applying it to the male pins. Then plug and unplug 2 or 3 times to clean the pins. You can add a little extra after making the connection as well.

Castle Link Settings

When paired with a Castle ESC there are a number of programmable settings related specifically to Castle motors in the Castle Link Programming Suite, which is accessed via the Castle Link USB adapter and freely downloadable Castle Link Windows software, or the Castle Link App and a B-LINK Bluetooth Adapter.

1. Motor Temperature Cutoff

When this setting is enabled on a sensored motor, the controller will shut off if the motor reaches the specified temperature (120F to 210F, user selectable) as indicated by its internal temperature sensor. Note: This only works with a sensored ESC with the sensor wire connected between the motor and ESC.

2. Sensorless Motor Timing

Motor timing advance changes the timing advance range used on the motor. Generally, low advance gives more efficiency and less power. High advance gives more power at the expense of efficiency (motor heat). Every system will respond to changes in advance differently.

3. Motor Direction

The Motor Direction setting allows you to reverse the direction of rotation on your motor shaft. See “Reversing Motor Direction” table below for additional information.

4. Motor Start Power

This setting controls how much power is allowed into the motor to get it started for the first few revolutions from a dead stop. Each power system is different, so it’s best to start with a low setting first, and experiment to find which performs best for you from there.

GENERAL TIPS TO MAINTAIN YOUR BRUSHLESS MOTOR

1. Keep it Clean: Regularly clean your motor to remove any dirt, dust, or debris that may accumulate during use. Use a soft brush or compressed air to gently clean the motor's exterior and cooling vents. Avoid using excessive force or abrasive materials that could damage the motor.

2. Check for Damage: Inspect the motor regularly for any signs of damage, such as loose wires, bent shafts, or worn bearings. If you notice any issues, address them promptly to prevent further damage or performance degradation.

Cleaning and inspection of motor after use.

3. Proper Gear Mesh: Ensure that the gear mesh between the motor and the drivetrain is correctly set. Improper gear mesh can cause excessive wear on the motor and reduce efficiency. Refer to your car's manual for instructions on setting the gear mesh correctly.

Gear Mesh Check

4. Monitor Motor Temperature: Keep an eye on the motor's temperature during operation. Excessive heat can damage the motor and decrease its lifespan. If the motor becomes too hot, consider adjusting the gearing, improving airflow around the motor, or adding a heat sink or fan to help with cooling.

5. Avoid Overheating: Extended periods of full-throttle operation or excessive load can lead to overheating. Give your motor occasional breaks to cool down, especially during long and intense running sessions. Overheating can cause damage to the motor's windings and magnets.

Temperature Check

6. Use the Correct Battery: Ensure that you are using a compatible and properly rated battery for your brushless motor. Using an under-powered or over-powered battery can strain the motor and lead to premature wear or damage. Follow the manufacturer's recommendations for battery specifications.

7. Store Properly: Avoid storing your car in extreme temperatures and direct sunlight, as they can degrade the motor's performance and components over time.

8. Remember, always consult the manufacturer's guidelines and specific recommendations for your brushless motor model. Proper maintenance and care will not only ensure a longer lifespan for your motor but also enhance the overall performance and enjoyment of your remote-control car.

Additional Resources

We can guarantee that our website contains the most up to date information about our products. Each Castle ESC and Motor have detailed descriptions, technical specifications and product use statements on our website and we strongly encourage anyone who has or is interested in purchasing a Castle setup to check out the corresponding product page(s) on our website. We do our best to provide this information to the Castle resellers globally, however we cannot guarantee their accuracy or level of detail.

Castle Creations is committed to providing the best assistance possible. If you encounter any challenges or have questions while using our products, our dedicated support team is just a phone call or email away. We're here to lend a helping hand, offering expert guidance and troubleshooting tips to ensure that your R/C journey remains smooth and enjoyable.

Monday-Friday 9am-4pm CST

Tech Support: (913) 390-6939 Option 1

Tech Support Email: https://home.castlecreations.com/contact-support

Tech Support Website: https://home.castlecreations.com/tech-support

If there’s a topic you’d love to see us cover in a future blog, let us know in the comments—we’re always looking for fresh ideas and insights from our community.

🙌 Thanks for reading, and we’ll catch you in the next one!

RC truck pulling is one of the most torque-hungry, community-driven niches in the RC hobby. . Whether you’re curious about the history, rules, events, or how to get started, this guide will pull you in.